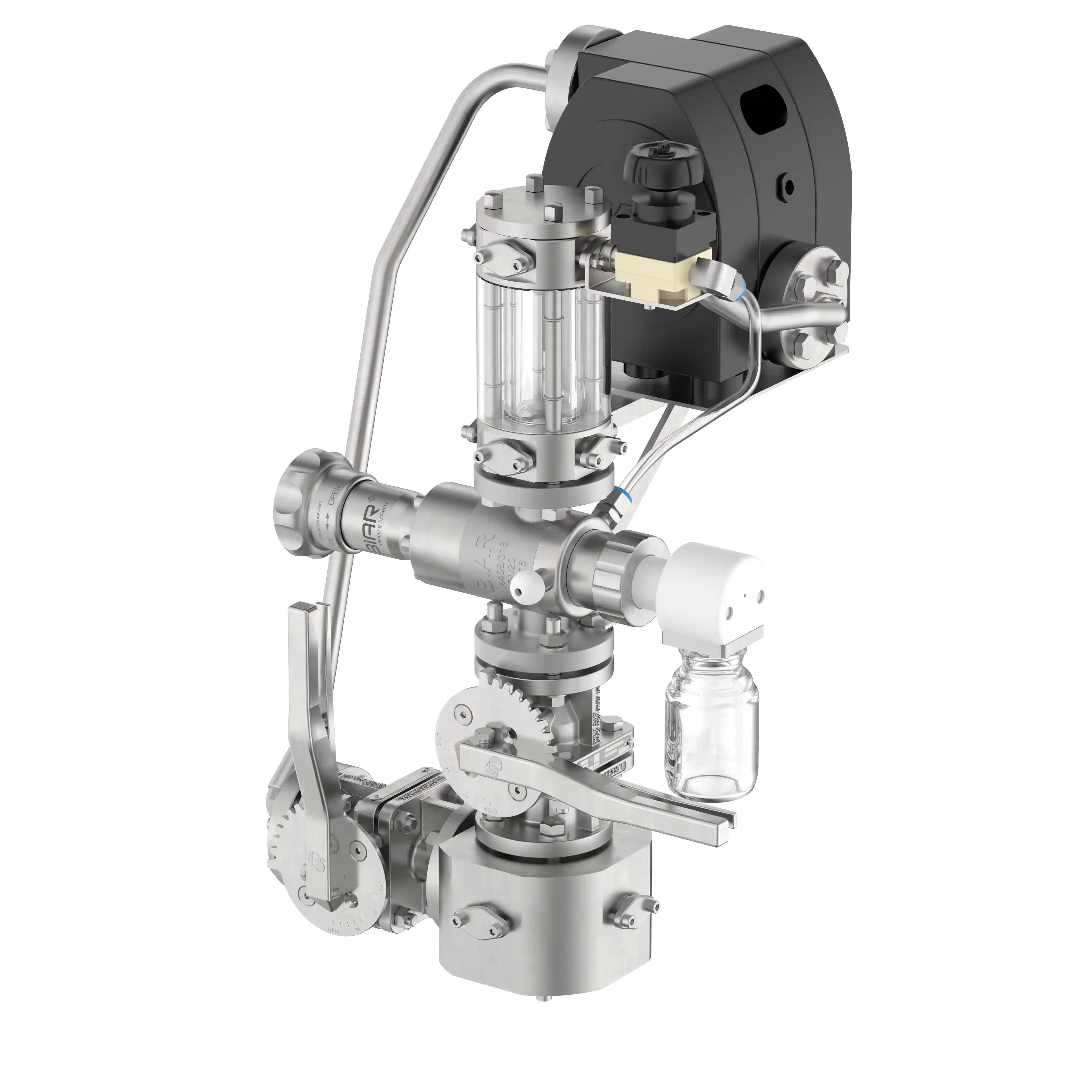

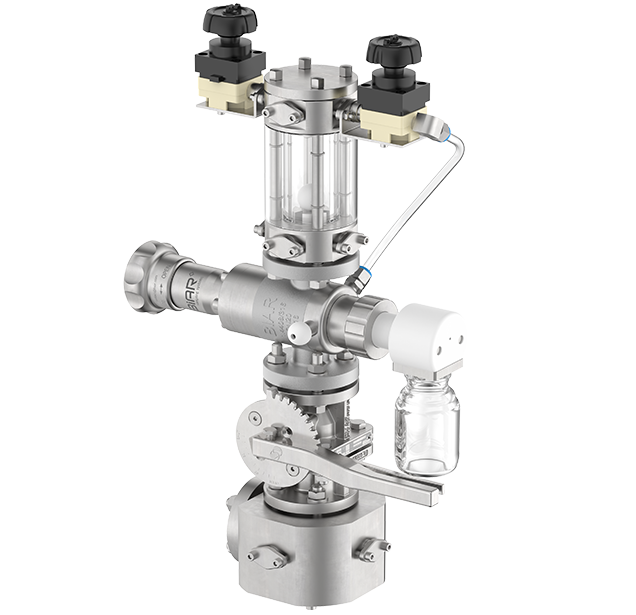

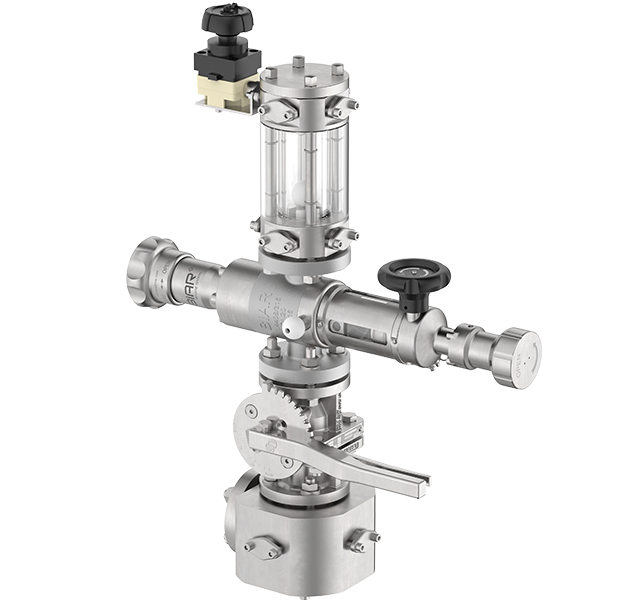

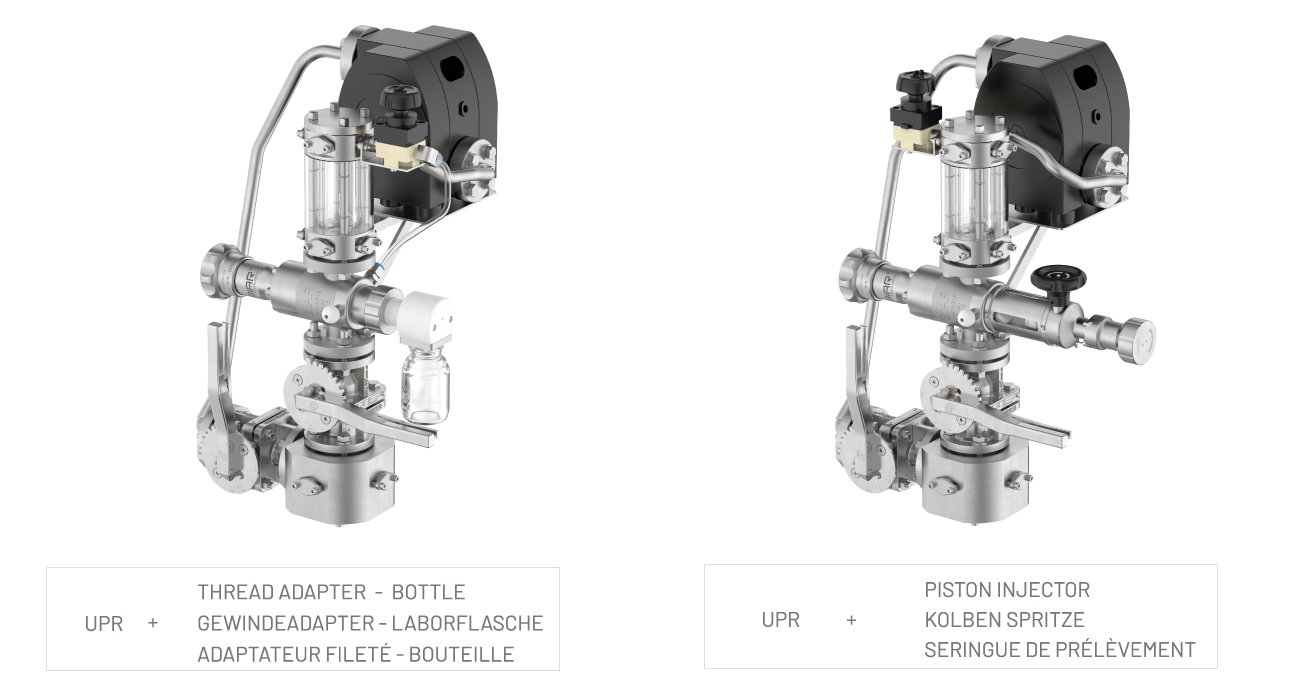

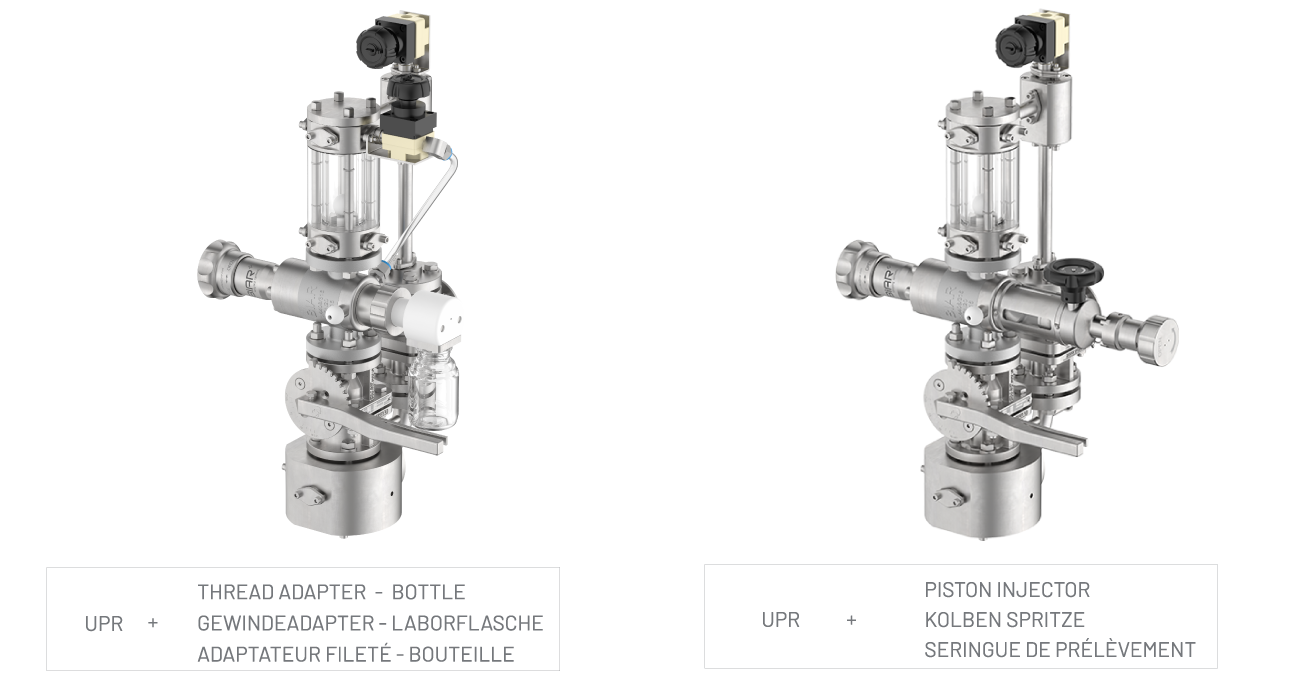

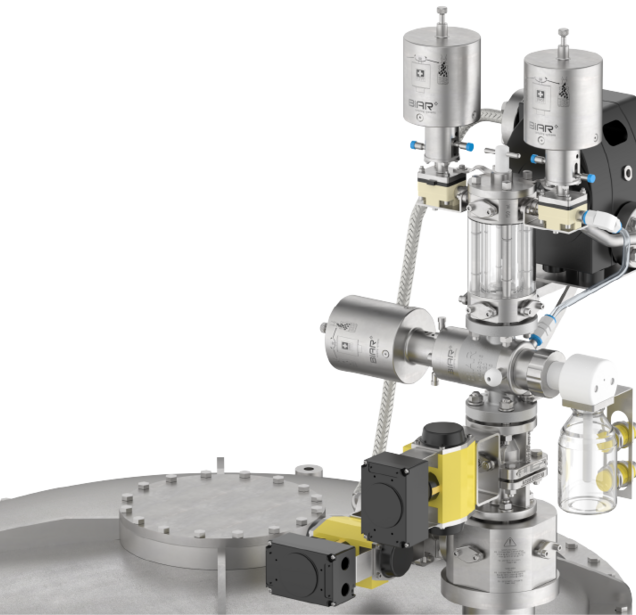

VARIANTS

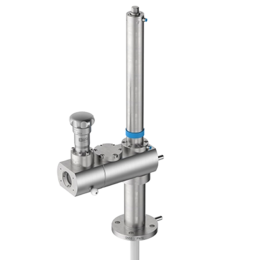

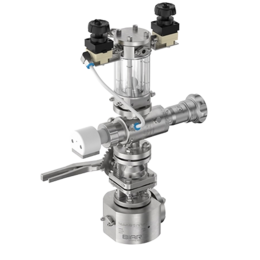

The UPR top of reactor sampling systems are designed with drive possibilities and the sampling unit options. Depending on the product's characteristics and safety requirements, BIAR SA provides two options: a bottle adapter or a PFA-coated piston injector. This versatility ensures safe and efficient sampling, even in high-risk environments.