ENP

- PFA lined sampling valve with nitrogen rinsing

- Wafer type

- Horizontal assembly

- Multifunction

Suitable for sampling chemicals that are both highly corrosive and highly reactive, the PFA-coated ENP sampling valve (without flange) with nitrogen rinsing enables representative sampling to be carried out easily and safely without interrupting manufacturing processes. It is designed to be installed on a horizontal line. Nitrogen rinsing through the spindle plays an essential role in inertising and cleaning the bottle, preventing undesirable reactions and eliminating the risk of explosion or ignition, while preserving the purity of the sample. The ENP's one-piece design reduces dead zones and ensures a perfect sealing. Initially manufactured in stainless steel with a pure PFA coating, it is also available in antistatic PFA to meet specific requirements. The wafer design without flange reduces pressure losses and space requirements. Its ingenious, robust bayonet connection system makes it possible to use different bottles and accessories without changing the sampling system. It facilitates management while limiting costs. Based on a modular concept, the ENP sampling system, also known as PRISEMASSON®, can be adapted to suit different needs and requirements. This sampling system offers significant advantages in terms of performance and cost.

Spécifications techniques

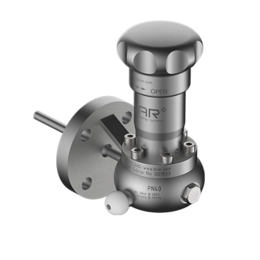

Schéma indicatif d'une vanne d'échantillonnage ENP, revêtue PFA avec rinçage à l'azote, équipée d'un actionneur de type volant magique VMB

- DIN

- ANSI

- 16

- 150

| xxxxxxxx | 25 | 118 | 113 | 25 | 115 | 26 | 85 | 4x13 | 9.1 |

|---|---|---|---|---|---|---|---|---|---|

| xxxxxxxx | 50 | 131.5 | 133 | 50 | 165 | 26 | 125 | 4x18 | 12.1 |

| NrArticle | NPS | h1 | h2 | d1 | D | d2 | k | nxd | Kg |

|---|---|---|---|---|---|---|---|---|---|

| 03692200 | 1 | 118 | 99.5 | 25 | 115 | 26 | 79.2 | 4x15 | 9.1 |

| xxxxxxxx | 2 | 131.5 | 146.5 | 50 | 165 | 26 | 120.7 | 4x19 | 12.1 |

| TS (°C) | -20 | 0 | 100 | 150 | 180 max |

|---|---|---|---|---|---|

| PN16 (bar) | 16 | 16 | 14.2 | 12.5 | 11.5 |

| °F | (°C) | -4 | (-20) | 32 | (0) | 212 | (100) | 302 | (150) | 370 | (180)max |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 150# | psi (bar) | 230 | (15.9) | 230 | (15.9) | 195 | (15.3) | 175 | (12) | 166 (11.5) |

Each ENP Inline sampling valve can be configured according to production specifications and sampling parameters

Sealing

Stem Gasket PFA

Materials

In their initial configuration, the sampling valves feature standard PFA lining, yet they are also offered with an antistatic PFA alternative

Actuators

VLN sampling valves can be configured with different drives

Vent hole principle

The venting hole fitted to each ENP sampling valve prevents overpressure and explosions

Il peut être connecté de différentes manières

Vent hole principle

The vent hole in our sampling systems prevents overpressure in the container and allows for the recovery of toxic gases.

NITROGEN RINSING THROUGH THE SPINDLE

ENP samplers incorporate a spindle-based nitrogen flusing feature that enables bottle rinsing and inertization.

NITROGEN RINSING THROUGH THE SPINDLE

If bottle rinsing is required, the ECB samplers can be configured with the nitrogen flushing option

Accessories

ENP In-line sampling valves are compatible with a wide range of accessories

Inline sampling valves

BIAR SA offers inline sampling valves that can be adapted to your sampling and production constraints