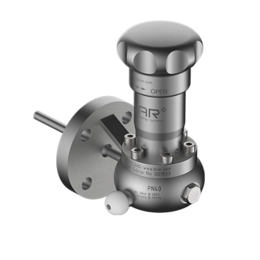

LLB

- Inline sampling valve

- With flanges

- Lateral assembly

- Multifonction

The LLB lateral mounting spindle sampling valve enables representative sampling to be carried out safely, without interrupting manufacturing processes. Initially manufactured in stainless steel with a PTFE seal, it is also available in other alloys and seals, depending on specific requirements. Its great flexibility in terms of connections makes it ideal for transport, loading and unloading operations. In chemical and petrochemical plants, the LLB valve ensures safety when sampling hazardous and toxic liquids such as halogens, Grignard reagents, alkylating agents and concentrated acids. Their unique quick connection system for receptacles means that different bottles or accessories can be used without changing the sampling system. It facilitates management while limiting costs. Based on a modular concept, the LLB sampling system, also known as PRISEMASSON®, can be modulated according to requirements and needs (materials, sealing, actuators, options).

TECHNICAL DETAILS OF AN MLB INLINE SAMPLING VALVE

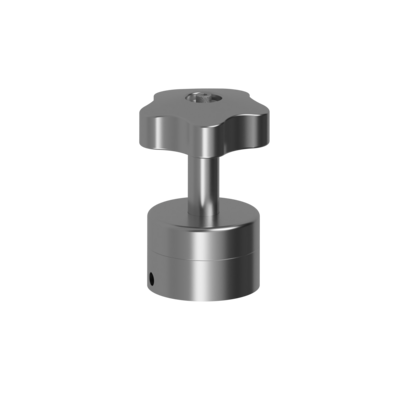

Illustrative diagram of a standard LLB sampling valve, without additional options, featuring the VMB magic wheel actuator

- DIN

- ANSI

- 16

- 40

- 150

- 300

| NrArticle | DN | L1 | L2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|

| xxxxxxxx | 15 | 100 (i) | 100 (i) | 95 | 65 | 4x14 | 5.7 |

| xxxxxxxx | 20 | 100 (i) | 100 (i) | 105 | 75 | 4x14 | 6 |

| xxxxxxxx | 25 | 100 (i) | 100 (i) | 115 | 85 | 4x14 | 6.1 |

| xxxxxxxx | 32 | 100 (i) | 100 (i) | 140 | 100 | 4x18 | 6.2 |

| xxxxxxxx | 40 | 100 (i) | 100 (i) | 150 | 110 | 4x18 | 6.3 |

| xxxxxxxx | 50 | 100 (i) | 100 (i) | 165 | 125 | 4x18 | 8.1 |

| xxxxxxxx | 65 | 100 (i) | 100 (i) | 185 | 145 | 8(4)x18 | 8.7 |

| 02016900 | 80 | 100 (i) | 100 (i) | 200 | 160 | 8x18 | 9.8 |

| xxxxxxxx | 100 | 100 (i) | 100 (i) | 220 | 180 | 8x18 | 11.9 |

| NrArticle | DN | L1 | L2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|

| 02504601 | 15 | 100 (i) | 100 (i) | 95 | 65 | 4x14 | 5.7 |

| 01420001 | 20 | 100 (i) | 100 (i) | 105 | 75 | 4x14 | 6 |

| 01119206 | 25 | 100 (i) | 100 (i) | 115 | 85 | 4x14 | 6.1 |

| 00937200 | 32 | 100 (i) | 100 (i) | 140 | 100 | 4x18 | 6.2 |

| 02396100 | 40 | 100 (i) | 100 (i) | 150 | 110 | 4x18 | 6.3 |

| 03201001 | 50 | 100 (i) | 100 (i) | 165 | 125 | 4x18 | 8.1 |

| xxxxxxxx | 65 | 100 (i) | 100 (i) | 185 | 145 | 8x18 | 8.7 |

| xxxxxxxx | 80 | 100 (i) | 100 (i) | 200 | 160 | 8x18 | 9.8 |

| 04821100 | 1100 (i) | 100 (i) | 100 | 235 | 190 | 8x22 | 11.9 |

| NrArticle | NPS | L1 | L2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|

| 01153902 | 1/2 | 100 (i) | 100 (i) | 89 | 60.5 | 4x15.7 | 5.1 |

| 04620501 | 3/4 | 100 (i) | 100 (i) | 98 | 69.6 | 4x15.7 | 5.5 |

| 01291502 | 1 | 1100 (i) | 100 (i) | 108 | 79.2 | 4x15.7 | 5.7 |

| xxxxxxxx | 1 1/4 | 100 (i) | 100 (i) | 117 | 88.9 | 4x15.7 | 6.2 |

| 05331500 | 1 1/2 | 100 (i) | 100 (i) | 127 | 98.6 | 4x15.7 | 6.4 |

| 01168503 | 2 | 100 (i) | 100 (i) | 152 | 121 | 4x19.1 | 7.9 |

| xxxxxxxx | 2 1/2 | 100 (i) | 100 (i) | 178 | 139.7 | 4x19.1 | 8.7 |

| 02056801 | 3 | 100 (i) | 100 (i) | 190 | 152.4 | 4x19.1 | 9.8 |

| 04003800 | 4 | 100 (i) | 100 (i) | 229 | 190.5 | 8x19.1 | 11.9 |

| NrArticle | NPS | L1 | L2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|

| 01884000 | 1/2 | 100 (i) | 100 (i) | 95 | 66.6 | 4x15.7 | 5.1 |

| 03069200 | 3/4 | 100 (i) | 100 (i) | 117 | 82.6 | 4x19.1 | 5.5 |

| 02377100 | 1 | 1100 (i) | 100 (i) | 124 | 88.9 | 4x19.1 | 5.7 |

| xxxxxxxx | 1 1/4 | 100 (i) | 100 (i) | 133 | 98.6 | 4x19.1 | 6.5 |

| 02626500 | 1 1/2 | 100 (i) | 100 (i) | 156 | 114.3 | 4x22.4 | 6.4 |

| 04534500 | 2 | 100 (i) | 100 (i) | 165 | 127 | 8x19.1 | 7.9 |

| xxxxxxxx | 2 1/2 | 100 (i) | 100 (i) | 190 | 149.4 | 8x22.4 | 8.9 |

| 04535000 | 3 | 100 (i) | 100 (i) | 210 | 168.1 | 8x22.4 | 9.8 |

| xxxxxxxx | 4 | 100 (i) | 100 (i) | 254 | 200.2 | 8x22.4 | 11.9 |

| °C | -40 | 0 | 100 | 150 | 200 |

|---|---|---|---|---|---|

| PN16 | 16 | 16 | 15.1 | 13.7 | 12.7 |

| °C | -40 | 0 | 100 | 150 | 200 |

|---|---|---|---|---|---|

| PN40 | 16 | 16 | 16 | 16 | 16 |

| °F | (°C) | -20 | (-29) | 0 | (-18) | 200 | (94) | 300 | (149) | 400 | (205) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 150# PSI | (BAR) | 232 | (16) | 232 | (16) | 195 | (14) | 175 | (12) | 160 | (11) |

| °F | (°C) | -20 | (-29) | 0 | (-18) | 200 | (94) | 300 | (149) | 400 | (205) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 300# PSI | (BAR) | 232 | (16) | 232 | (16) | 232 | (16) | 1232 | (16) | 232 | (16) |

Each LLB Inline sampling valve can be configured according to production specifications and sampling parameters.

Various sealings possibilities

The LLB sampling valves can be equipped with various types of sealing

LLB body can be designed in various alloys

In its standard version, the LLB sampling valves is made from stainless steel. It is also available in other alloys.

Actuator options for the LLB sampling system

LLB sampling valves can be configured with different drives

Various possible connections

LLB in-line samplers can be connected in various different ways and adapted to different uses (in-line, loading, unloading, transport)

Connections

BIAR inline sampling valves can be connected in a number of ways.

Vent hole principle

The venting hole fitted to each LLB sampling valve prevents overpressure and explosions.

Il peut être connecté de différentes manières

Vent hole principle

The vent hole in our sampling systems prevents overpressure in the container and allows for the recovery of toxic gases.

Nitrogen rinsing through the spindle

If bottle rinsing is required, the LLB samplers can be configured with the nitrogen flushing option

NITROGEN RINSING THROUGH THE SPINDLE

If bottle rinsing is required, the ECB samplers can be configured with the nitrogen flushing option

Accessories designed for use with LLB inline sampling valves

LLB in-line samplers are compatible with a wide range of accessories

Inline sampling valves

BIAR SA offers inline sampling valves that can be adapted to your sampling and production constraints