ENB

- Inline sampling valve with nitrogen rinsing

- Wafer type

- Horizontal assembly

- Multifunctional

Designed for horizontal or vertical assembly, the ENB sampling valve with rinsing without flange (wafer type) offers a reliable and practical solution for representative sampling without interrupting production processes. Nitrogen rinsing through the spindle plays an essential role in inertising and cleaning the bottle, preventing undesirable reactions and eliminating the risk of explosion or ignition, while preserving the purity of the sample. Its ingenious quick connection sampling system allows a variety of bottles and accessories to be used without having to replace the sampling system, simplifying management while keeping costs under control. The standard version of this valve is manufactured in stainless steel, but it is also available in other alloys to meet specific requirements. The wafer design without flange reduces pressure losses and space requirements. Based on a modular concept, this sampling valve, also known as PRISEMASSON®, offers great flexibility, adapting perfectly to different requirements and needs. It is particularly valuable in critical environments where quality and safety are imperatives.

Technical Specifications for ENB Sampling Valves

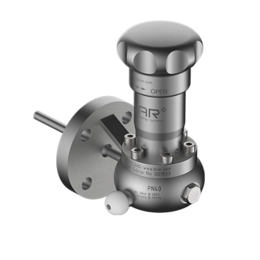

Illustrative drawing of a ENB sampling valve, with nitrogen rinsing, featuring the VMB magic wheel actuator type

- DIN

- ANSI

- 16

- 40

- 150

- 300

| NrArticle | DN | L | h1 | h2 | d1 | d2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|---|---|---|

| xxxxxxxx | 15 | 60 | 50.5 | 107 | 24 | 20 | 129 | 65 | 4x14 | 8.4 |

| 02367803 | 25 | 60 | 60.5 | 113 | 36 | 26 | 145 | 85 | 4x14 | 9.8 |

| xxxxxxxx | 40 | 60 | 78 | 120 | 50 | 26 | 175 | 110 | 4x18 | 11.0 |

| 02463203 | 50 | 60 | 85.5 | 126 | 62 | 26 | 189 | 125 | 4x18 | 14.3 |

| xxxxxxxx | 80 | 60 | 103 | 140 | 90 | 26 | 220 | 160 | 8x18 | 16.7 |

| xxxxxxxx | 100 | 60 | 120.5 | 153 | 116 | 26 | 254 | 180 | 8x18 | 20 |

| NrArticle | DN | L | h1 | h2 | d1 | d2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|---|---|---|

| xxxxxxxx | 15 | 60 | 50.5 | 107 | 24 | 20 | 129 | 65 | 4x14 | 8.4 |

| xxxxxxxx | 25 | 60 | 60.5 | 113 | 36 | 26 | 145 | 85 | 4x14 | 9.8 |

| xxxxxxxx | 40 | 60 | 78 | 120 | 50 | 26 | 175 | 110 | 4x18 | 11.0 |

| xxxxxxxx | 50 | 60 | 85.5 | 126 | 62 | 26 | 189 | 125 | 4x18 | 14.3 |

| xxxxxxxx | 80 | 60 | 103 | 140 | 90 | 26 | 220 | 160 | 8x18 | 16.7 |

| xxxxxxxx | 100 | 60 | 120.5 | 153 | 116 | 26 | 254 | 190 | 8x22 | 20 |

| NrArticle | NPS | L | h1 | h2 | d1 | d2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|---|---|---|

| xxxxxxxx | 3/4 | 60 | 54.3 | 110 | 24 | 26 | 135 | 69.9 | 4x15.7 | 9.7 |

| xxxxxxxx | 1 | 60 | 60.5 | 113 | 36 | 26 | 145 | 79.2 | 4x15.7 | 10.3 |

| xxxxxxxx | 1 1/2 | 60 | 78 | 120 | 50 | 26 | 175 | 98.6 | 4x15.7 | 13.0 |

| xxxxxxxx | 2 | 60 | 85.5 | 126 | 62 | 26 | 189 | 120.7 | 4x19.1 | 14.1 |

| xxxxxxxx | 2 1/2 | 60 | 95.5 | 134 | 78 | 26 | 220 | 139.7 | 4x19.1 | 14.8 |

| xxxxxxxx | 3 | 60 | 103 | 140 | 90 | 26 | 254 | 152.4 | 4x19.1 | 17.0 |

| xxxxxxxx | 4 | 60 | 120.5 | 153 | 116 | 26 | 302 | 190.5 | 8x19.1 | 20.3 |

| NrArticle | NPS | L | h1 | h2 | d1 | d2 | D | k | nxd | Kg |

|---|---|---|---|---|---|---|---|---|---|---|

| xxxxxxxx | 3/4 | 60 | 54.3 | 110 | 24 | 26 | 135 | 82.6 | 4x19.1 | 9.7 |

| xxxxxxxx | 1 | 60 | 60.5 | 113 | 36 | 26 | 145 | 88.9 | 4x19.1 | 10.3 |

| xxxxxxxx | 1 1/2 | 60 | 78 | 120 | 50 | 26 | 175 | 114.3 | 4x22.4 | 13.0 |

| xxxxxxxx | 2 | 60 | 85.5 | 126 | 62 | 26 | 189 | 127 | 8x19.1 | 14.1 |

| xxxxxxxx | 2 1/2 | 60 | 95.5 | 134 | 78 | 26 | 220 | 139.7 | 4x19.1 | 14.8 |

| xxxxxxxx | 3 | 60 | 103 | 140 | 90 | 26 | 254 | 168.1 | 8x22.4 | 17.0 |

| xxxxxxxx | 4 | 60 | 120.5 | 153 | 116 | 26 | 302 | 200.2 | 8x22.4 | 20.3 |

| °C | -40 | 0 | 100 | 150 | 200 |

|---|---|---|---|---|---|

| PN16 | 16 | 16 | 15.1 | 13.7 | 12.7 |

| °C | -40 | 0 | 100 | 150 | 200 |

|---|---|---|---|---|---|

| PN40 | 16 | 16 | 16 | 16 | 16 |

| °F | (°C) | -20 | (-29) | 0 | (-18) | 200 | (94) | 300 | (149) | 400 | (205) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 150# | psi (bar) | 232 (16) | 232 (16) | 195 (14) | 175 (12) | 160 (11) |

| °F | (°C) | -20 | (-29) | 0 | (-18) | 200 | (94) | 300 | (149) | 400 | (205) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 300# | psi (bar) | 232 (16) | 232 (16) | 232 (16) | 232 (16) | 232 (16) |

Unlock Customization: Tailor Every ENB Inline Sampling Valve to your unique Production specification and sampling Needs!

Sealings

Versatile Sealing Options: Customize Your ENB Sampling Valves with a Range of Sealing Types!

MATERIAL

In its standard version, the ENB sampling valves are made from stainless steel. They are also available in various alloys

ACTUATORS

ENB sampling valves can be configured with different drives

Vent hole principle

The venting hole fitted to each ENB sampling valve prevents overpressure and explosions.

Il peut être connecté de différentes manières

Vent hole principle

The vent hole in our sampling systems prevents overpressure in the container and allows for the recovery of toxic gases.

NITROGEN RINSING THROUGH THE SPINDLE

If bottle rinsing is required, the ECB samplers can be configured with the nitrogen flushing option

ACCESSORIES

ENB In-line sampling valves are compatible with a wide range of accessories

Inline sampling valves

BIAR SA offers inline sampling valves that can be adapted to your sampling and production constraints